*note: if interested in item please "Add to Order", you can then go over all items before submitting request.

Description

In new well systems, use Clay Dispersant liquid polymer to break down drilling mud, remove natural clays and speed up well development.

• Clay Dispersant polymer uses liquid dispersant chemistry specifically designed to remove mud and clay from the well environment

• Successfully develops new wells without using phosphates

• Eliminates food source for bacteria (100 percent water soluble, readily flushed from well)

• Rehabilitates old wells plugged with clays, silts and fines

• NSF certified for potable water well use

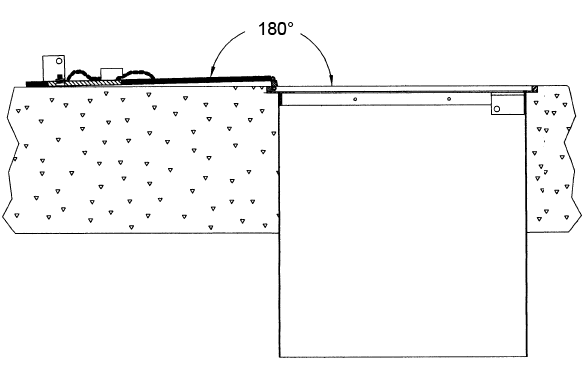

Pre-treatment and Application

For optimal removal of bentonite drilling fluids, separately pre-treat the well with 1,500 ppm chlorine to break down the polymers that are included in most commercial bentonite products. Thoroughly f lush the chlorine solution from the well. Determine the drilling fluid volume and apply Clay Dispersant polymer at the rate of 1 gal. per 500 gal. of drilling fluid in the system to be broken down and removed from the well. Vigorously agitate by mechanical means for several hours (approximately 1/2 hour per 20 ft. of intake). If left in the well overnight, agitate before pumping out. Allow a minimum of 6 to 8 hours contact time, downhole.

In older well systems use Clay Dispersant polymer to remove fine sands, mud and clays that have filled in the gravel pack and borehole. Use at a rate of 1 gal. per 300 gal. of water. Vigorously agitate (by mechanical means), allowing the solution to stand in the well overnight and repeat the agitation the next day, before pumping out. Allow a minimum of 6 to 8 hours contact time, downhole.