*note: if interested in item please "Add to Order", you can then go over all items before submitting request.

Description

Bio Dispersant is a unique polymeric-acid chemistry that is the most effective product available for breaking down biofilm and dispersing mineral salts. Bio Dispersant provides a considerable boost to any acid-cleaning operation, is readily biodegradable and may be used to treat potable water systems and related equipment.

Bio Dispersant maintains the acid reaction, holding minerals in suspension at pH levels up to 5.0 for thorough removal of biological material during flushing. Without the use of Bio Dispersant, dissolved minerals will drop out at pH levels above 3.0.

• Dislodges biofilm masses associated with iron oxidizing, sulfate-reducing and more prevalent slime forming bacteria, which are not removed by mineral acids alone

• Sequesters iron and inhibits corrosion on metal surfaces - iron sequestering allows the chemical solution to remove heavy accumulation of iron compounds

• Contains the best NSF certified inhibitor for water wells, protecting all forms of metal in the system, and will not attack plastic, neoprene or other synthetic materials - eliminating the need for acid inhibitors

• Provides passivation of metals when used with phosphoric acid

• NSF certified for cleaning potable water wells, pipelines and filter systems

Application

Bio Dispersant is designed for use with acid solutions to enhance the acid cleaning reaction and improve overall cleaning. Standard dosage is 3 percent (1 to 2 percent for maintenance). It is recommended that well construction and performance history be submitted, along with water samples for lab analysis, to properly determine dosage on large municipal and industrial wells.

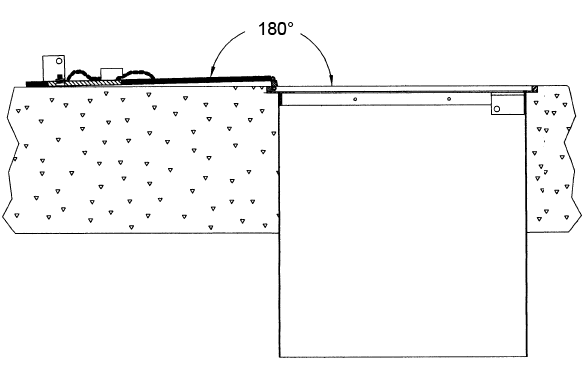

1. Surface prepare a solution of water, acid and Bio Dispersant equal to approximately 40 percent of the total static volume into a vessel of appropriate size. First add water, then acid, then Bio Dispersant. (Note: NEVER add water to acid! DO NOT mix Bio Dispersant directly to commercial concentrations of liquid acid, as polymer destruction may occur).

2. Place the solution evenly across the intake zone, ensuring contact with affected areas at the recommended concentration. Agitate the cleaning solution to enhance the effectiveness of cleaning.

3. The solution should remain in contact for 18 to 48 hours, depending on the nature of the deposit. Monitor the pH and keep it below 3.0 during treatment. If additional acid is needed (to lower pH), add an amount equal to approximately 20 percent of the initial volume of the acid solution amount of acid applied.

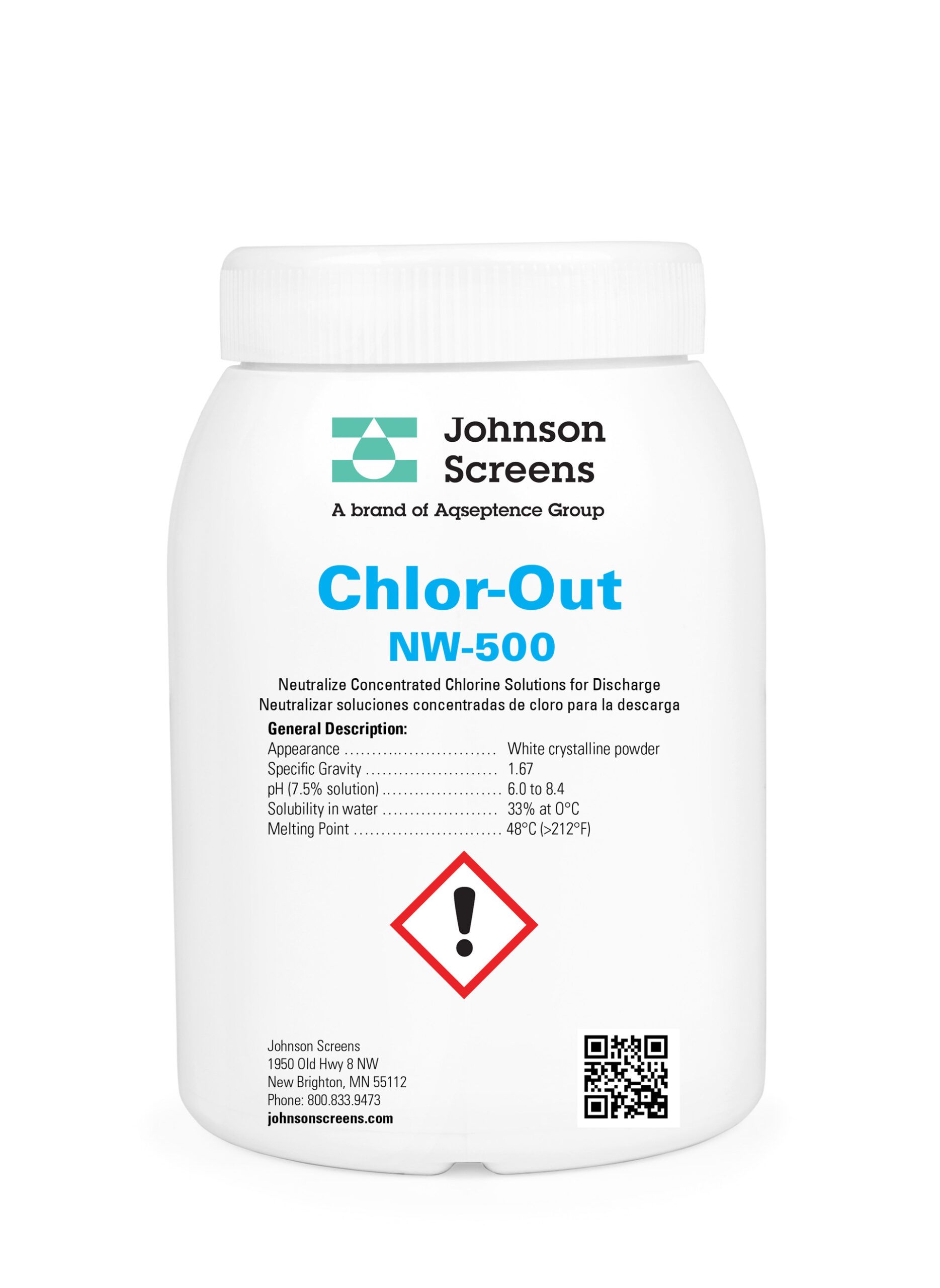

4. Discharge the acid solution from the well, neutralize at the surface with Neutralizer NW-600 and dispose in accordance with local regulations.